Soda Blast

East

How does Soda Blasting work?

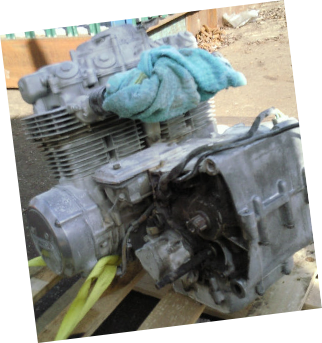

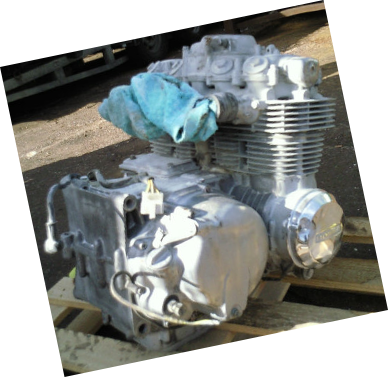

The process involves blasting sodium bicarbonate against the surface to be cleaned, using compressed air to accelerate the crystals to about 600 miles an hour. Unlike an abrasive, sodium bicarbonate particles remove contaminants by means of the energy release. When the particles 'explode' (crush) on contact with the surface the non-

Soda blasting also breaks down hydrocarbons through a process called, saponification which makes it highly suitable for cleaning equipment covered in fatty foods or grease. After Soda Blasting is complete just rinse off with water and the water soluble soda disappears.

The non-