Soda Blast

East

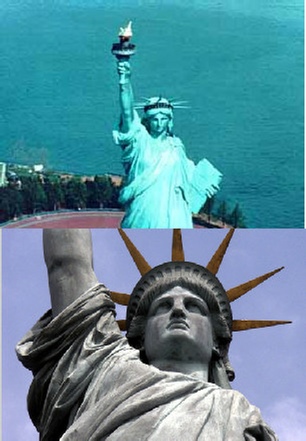

In 1972, when New York State engineers were looking for ways to clean the Statue of Liberty, they had many concerns involving issues of the environment, waste disposal, and protection of the statues surface itself. Any use of any abrasive material to clean the surface would have been very harmful to the soft copper plates and would have had environmental consequences for the water surrounding the statue.

Sodablasting was developed because it would not only do the job while having a negligible impact on the waterways and harbour, it was also non-

Just like the surface of the Statue of Liberty, this non abrasive action allows Soda Blasting to be used on surfaces that popular abrasive media would damage. i.e.: aluminium, stainless steel, brick, stone, glass, fibreglass, wood, some plastics, seals, bearings, splines, radiator cores, transmission cases, and hydraulic cylinders.

Sodablast particles remove contaminants by the energy released when the particles 'explode' as they come in contact with the surface to be cleaned. This results in no damage to underlying substrates. By contrast, sand and grit blasting can damage the underlying material.

Ferrous metals that have been sand blasted will require immediate coating to prevent rusting. By contrast, metal that has been cleaned using Soda blasting will rust at a much reduced rate and can be coated several days after blasting rather than hours.